Cold - Resistant Shock - Absorbing Rubber Sleeve for Cable Protection

Item specifics

- Color (General)

- Custom

- Material

- EPDM or other rubber materials: NBR, CR, IIR

- Length

- Custom

- Dimension

- Custom

- Temperature Range

- -45°C—125°C

- Shore Hardness

- 50-95 Shore A or customize

- Tensile strength

- 5~12Mpa

- Elongation at break

- 400%

Review

Description

Rubber Sleeve for Cable Protection Introduction

he rubber sleeve acts as a tough barrier, preventing the cable's outer insulation from being scratched or worn, thus maintaining the integrity of the electrical current flow.

Customization Options

RESRUB could produce the tubing with enough length to fully connect any size loop.

And available to custom colors, such as black, white, pink, etc.

Material Advantages

Crafted from high - quality rubber, it offers a comprehensive defense mechanism against various threats that cables may encounter.

Rubber Sleeve for Cable Protection Properties:

| Length | Customizable | OEM/ODM | Available |

| Reinforcement | Outer Layer Polyester Braiding for Enhanced Strength | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Gaming Case |

Technical Specification

EPDM rubber (ethylene propylene diene monomer rubber) is a type of synthetic rubber that is used in many applications, with outstanding resistance to oxygen, ozone, and sunlight. Additionally, it also has low temperature flexibility, excellent heat, water and steam resistance. Useful working temperature range is -60°C up to +150°C.

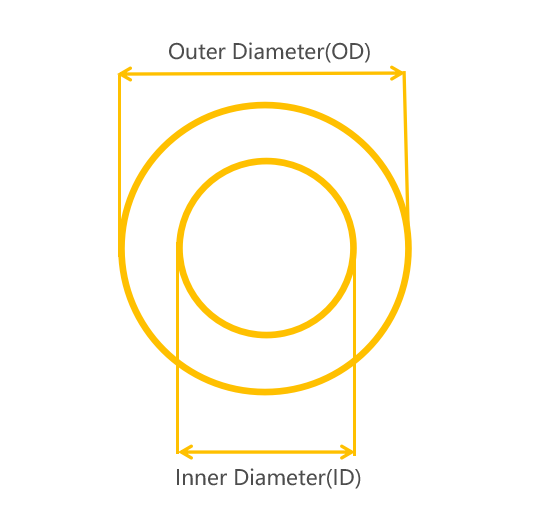

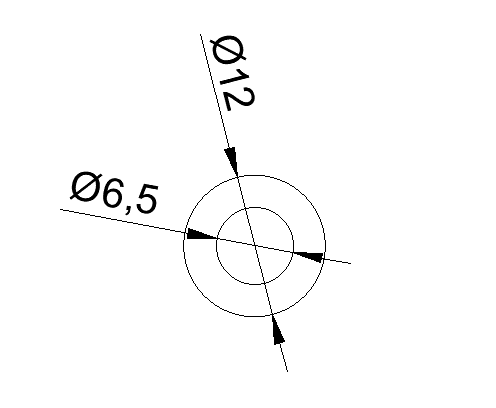

Notes on measuring pipe sizes:

Outer Diameter (OD): The measurement of the tubing's external surface and is typically the larger value.

Inner Diameter (ID): The internal measurement inside the tubing, critical for ensuring proper flow rates.

The most important thing to consider in tubing size is the combination of ID and OD. Selecting the correct measurement unit and ensuring precise compatibility are key to achieving an efficient and leak-proof liquid cooling system. These values also determine the wall thickness of your tubing, which in turn determines its flexibility and resistance to kinking.

What size tubing for liquid cooling?

The most common inner diameter(ID) sizes are 1/4" and 2/9". The outer diameter(OD) of tubing is the measurement between the outer wall of the outer wall of the opposite side. Common OD sizes for PC tubing are 1/2", 3/7", and 4/9". The wall thickiness of PC cooler tubing is the difference between the OD and ID.

what is coolant tubing made of?

EPDM is the typical tube material because of its strong resistance to heat, hot water, and eth ylene glycol, the most common antifreeze. In some cases, SBR or NBR may be used instead.

Can you use silicone tubing for coolant?

As such, silicone hose could be used in water coolant systems. However, EPDM tubber hoses are also suitable for a variety of water coolant applications and can be more cost-effective than other materials when large quantities are required.

Item | Rubber Sleeve for Cable Protection | |

Size | Customize | |

Material | EPDM or Silicone | |

Hardness | 50-95 Shore A or customize | |

Color | White or customize any color | |

Density | 0.6-1.45/cm³ | |

Temperature resistant | -45°C—125°C | |

Tensile strength | 5~12Mpa | |

Elongation at break | 200~900% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |