Eco-Friendly Rubber Sealing Strip Chemical-Resistant and Long-Lasting for Construction and Plumbing Systems

Item specifics

- Color (General)

- Custom

- Material

- EPDM or other rubber materials: NBR, CR, IIR

- Length

- Custom

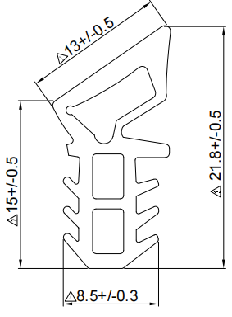

- Dimension

- Custom

- Temperature Range

- -45°C—125°C

- Shore Hardness

- 50-95 Shore A or customize

- Tensile strength

- 5~12Mpa

- Elongation at break

- 400%

Review

Description

Rubber Sealing Strip Introduction

These sealing strips find extensive applications in multiple industries. In the automotive industry, they are used around doors, windows, and trunks to improve the vehicle's acoustic insulation, waterproofing, and airtightness.

Customization Options

RESRUB could produce the tubing with enough length to fully connect any size loop.

And available to custom colors, such as black, white, pink, etc.

Material Advantages

Rubber sealing strips are typically made from materials such as EPDM, silicone, neoprene, and nitrile rubber. Each type of rubber has its own unique properties, making them suitable for different applications.

Rubber Sealing Strip Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available Logo | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Gaming Case |

Technical Specification

EPDM rubber (ethylene propylene diene monomer rubber) is a type of synthetic rubber that is used in many applications, with outstanding resistance to oxygen, ozone, and sunlight. Additionally, it also has low temperature flexibility, excellent heat, water and steam resistance. Useful working temperature range is -60°C up to +150°C.

What types of rubber are used for sealing strips?

Common types include EPDM for weather resistance, NBR for oil resistance, and silicone rubber for high - temperature applications.

How long does a rubber sealing strip last?

Lifespan depends on temperature, chemical exposure, mechanical stress, and UV exposure. Can range from a few years to over a decade.

How to install a rubber sealing strip?

Clean the surface, measure and cut the strip, then use adhesive or mechanical fasteners for installation.

Item | Rubber Strip | |

Size | Customize | |

Material | EPDM or Silicone | |

Hardness | 50-95 Shore A or customize | |

Color | White or customize any color | |

Density | 0.6-1.45/cm³ | |

Temperature resistant | -45°C—125°C | |

Tensile strength | 5~12Mpa | |

Elongation at break | 200~900% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |