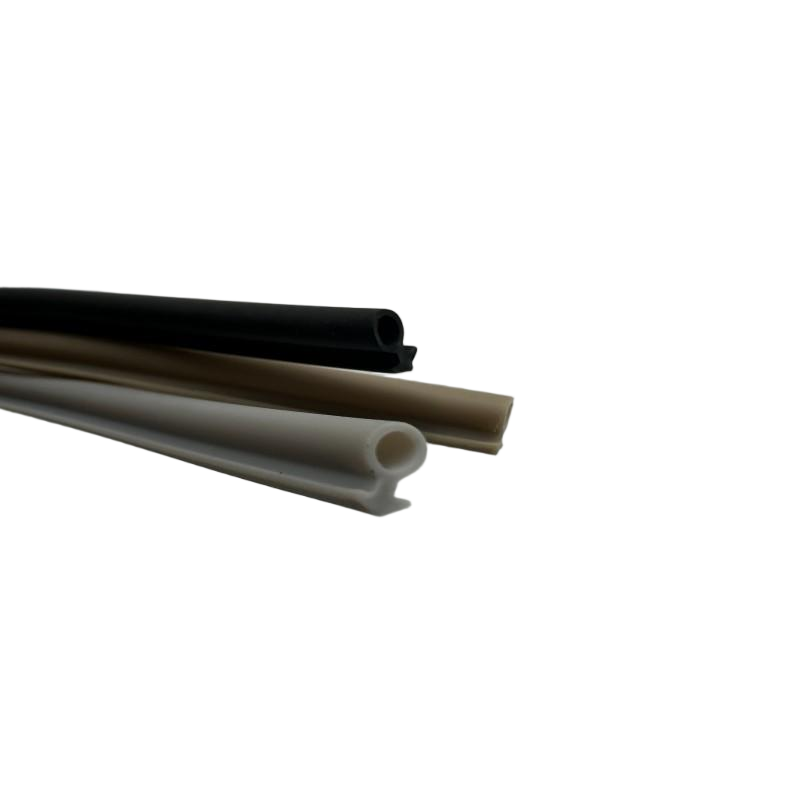

Scratch - Resistant Anti - Abrasion Luggage Seal Strips for Maintaining Aesthetic Appeal

- Model

- NO:F20241007

Item specifics

- Color (General)

- Custom

- Material

- TPV

- Length

- Custom

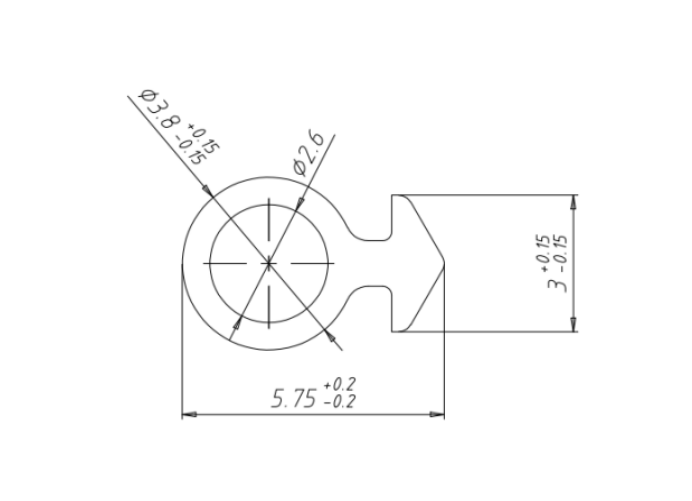

- Dimension

- Custom

- Temperature Range

- -45°C—125°C

- Shore Hardness

- 50-95 Shore A or customize

- Tensile strength

- 5~12Mpa

- Elongation at break

- 400%

Review

Description

Luggage Seal Strip Introduction

This strip effectively blocks water, dust, and dirt, keeping your belongings safe and clean during travel. Its anti - wear and tear properties ensure long - term use, even with frequent handling.

Customization Options

The Luggage Seal Strip, crafted from TPV (Thermoplastic Vulcanizate), combines the best properties of rubber and thermoplastics. TPV is a dynamically vulcanized alloy, where a cross-linked rubber phase is finely dispersed in a thermoplastic matrix.

Material Advantages

This unique structure endows TPV with high elasticity, excellent weather resistance, and good chemical stability, making it an ideal material for luggage seal strips that require durability and reliable performance.

Luggage Seal Strip Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Luggage |

Technical Specification

The production of TPV starts with the compounding of rubber and thermoplastic materials, typically polypropylene (PP) as the thermoplastic phase and ethylene propylene diene monomer (EPDM) as the rubber phase. Through a process of dynamic vulcanization under high temperature and shear force, the rubber phase is cross-linked while being dispersed in the thermoplastic matrix. This results in a material that can be easily processed using thermoplastic processing methods, such as extrusion, injection molding, or blow molding, to form the desired shape of the luggage seal strip.

How does TPV perform in wet or humid environments?

TPV has excellent water resistance and does not swell or degrade when exposed to moisture. It forms a tight seal to prevent water ingress, making it ideal for travel in rainy conditions or high-humidity environments. However, prolonged submersion in water is not recommended.

Can TPV seal strips be used for both hard-shell and soft-shell luggage?

Yes. TPV’s flexibility allows it to conform to curved surfaces on hard-shell luggage and adapt to the movement of soft-shell fabrics. Its resilience ensures a consistent seal regardless of the luggage type.

Is TPV resistant to UV radiation for outdoor use?

Yes, TPV has inherent UV resistance and does not yellow or crack easily when exposed to sunlight. For prolonged outdoor use (e.g., camping gear), choose UV-stabilized TPV variants for enhanced protection.

Item | Luggage Seal Strip | |

Size | Customize | |

Material | TPV | |

Hardness | 65±5 Shore A or customize | |

Color | Black or customize any color | |

Density | 0.97g/cm³ | |

Temperature resistant | -40°C—100°C | |

Tensile strength | ≥4.5Mpa | |

Elongation at break | ≥450% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |