Sound - Insulating Anti - Noise Door Seal Strips for Peaceful Indoor Environments

- Model

- JJD001

Item specifics

- Color (General)

- Custom

- Material

- EPDM or other rubber materials: NBR, CR, IIR

- Length

- Custom

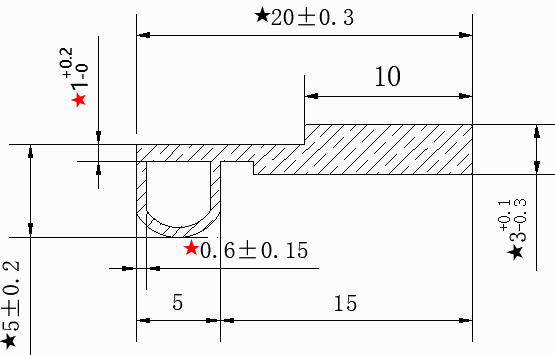

- Dimension

- Custom

- Temperature Range

- -45°C—125°C

- Shore Hardness

- 50-95 Shore A or customize

- Tensile strength

- 5~12Mpa

- Elongation at break

- 400%

Review

Description

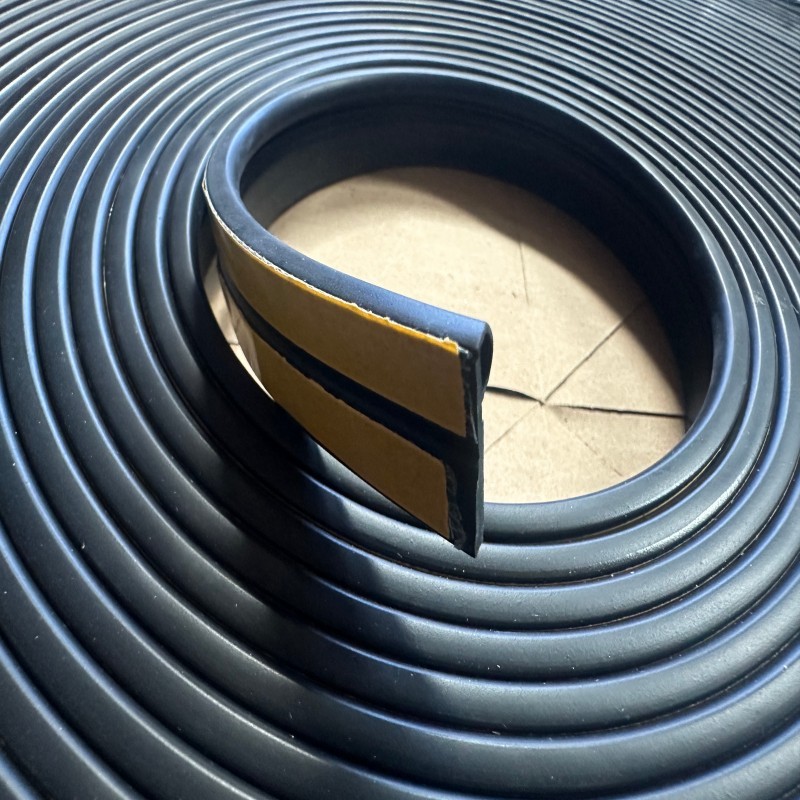

Door Seal Strip Introduction

Sealing Function

The primary role of the EPDM door seal strip is to create a tight and effective seal around doors. Whether it's for residential, commercial, or industrial doors, it fills the gaps between the door and the frame, preventing the ingress and egress of air, water, dust, noise, and pests. By blocking drafts, it helps improve energy efficiency in buildings, reducing heating and cooling costs. In the case of exterior doors, it keeps rain and snow out, protecting the interior from water damage. For interior doors, it can reduce noise transmission, creating a quieter and more comfortable environment.

Installation and Maintenance

Installing an EPDM door seal strip is a relatively straightforward process. Its flexibility allows it to be easily positioned and shaped to fit the contours of the door and frame. Many seal strips come with adhesive backing, making it simple to attach them by peeling off the protective film and pressing firmly onto the surface. Others can be installed using clips, screws, or other fastening methods. Maintenance requirements are minimal; due to EPDM’s durability and resistance to wear, the seal strip typically only needs periodic visual inspections to check for signs of damage or wear. With proper installation and normal use, an EPDM door seal strip can provide reliable sealing for several years, reducing the need for frequent replacements.

Cost - effectiveness

EPDM door seal strips offer a cost - effective solution for improving door performance. Their long service life, combined with low installation and maintenance costs, makes them an attractive investment. By reducing energy consumption, preventing water damage, and minimizing noise, they help save on utility bills, repair costs, and enhance the overall comfort and functionality of the space. Whether for a small home improvement project or a large - scale commercial installation, EPDM door seal strips provide significant value for money.

Door Seal Strip Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Construction & Renovation |

Material Properties

EPDM exhibits exceptional weather resistance, making it suitable for both indoor and outdoor use. It can endure prolonged exposure to sunlight, rain, snow, and extreme temperature fluctuations without degrading. Capable of maintaining flexibility from extremely cold temperatures as low as -40°C to high - heat conditions up to 120°C , EPDM prevents cracking in frigid weather and softening under intense heat, ensuring the seal strip retains its shape and effectiveness.

What's the role of a door seal strip?

It seals gaps around doors, blocking drafts, noise, dust, and insects. Keeps indoor temperature stable, reduces energy loss, and makes your space quieter and cleaner.

How to clean and maintain it?

Wipe with a damp cloth regularly. Use mild soap for stains. Check for wear like cracks or peeling. Replace if damaged for proper sealing

What affects its performance over time?

Frequent door opening/closing, extreme temperatures, humidity, and sunlight can cause the strip to wear, crack, or lose adhesion.

Item | Door Seal Strip | |

Size | Customize | |

Material | EPDM or Silicone | |

Hardness | 50-95 Shore A or customize | |

Color | Black or customize any color | |

Density | 0.6-1.45/cm³ | |

Temperature resistant | -45°C—125°C | |

Tensile strength | 5~12Mpa | |

Elongation at break | 200~900% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |