Flame - Retardant Anti - Fire Rubber Sleeves for Automotive Clamps in Safety - Sensitive Areas

- Model

- NO.WHF2024042002

Item specifics

- Color (General)

- Custom

- Material

- NBR

- Length

- Custom

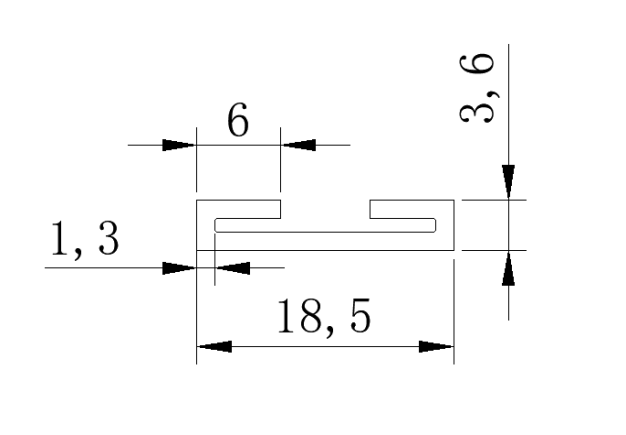

- Dimension

- Custom

- Temperature Range

- -40°C—120°C

- Shore Hardness

- 70 Shore A or customize

- Tensile strength

- 5~12Mpa

- Elongation at break

- 400%

- Density

- 1.3g/cm³

Review

Description

Rubber Sleeve for Automotive Clamps Introduction

Material Properties

NBR is a synthetic rubber copolymer known for its outstanding resistance to a variety of automotive fluids, including motor oils, fuels (such as gasoline and diesel), and lubricants. Its chemical structure allows it to withstand swelling and degradation when exposed to these substances, ensuring long - term reliability in automotive environments.

Function and Protection

The primary role of NBR rubber sleeves for automotive clamps is to protect the clamped components, like hoses, pipes, and cables. By acting as a buffer between the clamp and the underlying material, the NBR sleeve prevents abrasion, cuts, and indentations caused by the clamp's pressure. This protection helps maintain the integrity of the components, reducing the risk of leaks, cracks, or premature failure, which is crucial for the proper functioning of automotive systems.

Sealing Performance

NBR's inherent elasticity enables it to form a tight seal around the clamped object. As the clamp tightens, the NBR sleeve conforms to the shape of the component, creating a barrier that prevents the leakage of fluids or gases. This reliable sealing is vital in automotive applications, such as fuel lines, and air intake systems, where even minor leaks can lead to performance issues or safety hazards.

Rubber Sleeve for Automotive Clamps Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Vehicles & Transportation |

Installation precautions

When installing the rubber sleeve of the automobile fixture, it is necessary to clean the surface of the fixture first to ensure that there is no oil, rust and impurities, and cut the rubber sleeve accurately according to the size of the fixture. During the installation, the rubber sleeve should be evenly inserted into the fixture to avoid distortion and wrinkles. If it is necessary to glue and fix, the glue should be evenly applied and pressed firmly to prevent it from falling off and affecting the use effect.

1. Why should I choose NBR rubber sleeves for automotive clamps?

NBR rubber sleeves are an ideal choice for automotive clamps due to their exceptional resistance to a wide range of automotive fluids. NBR is highly resistant to oils, fuels, and greases commonly found in vehicles, which makes it perfect for protecting hoses, pipes, and cables that come into contact with these substances. This resistance prevents swelling, degradation, and leaks, ensuring the longevity and reliability of the clamped components. Additionally, NBR offers good mechanical strength and flexibility, allowing it to withstand the pressure from clamps while conforming well to the shape of the components, providing a secure and effective seal in various automotive applications.

2. How do NBR rubber sleeves perform in different temperature conditions?

NBR rubber sleeves can operate effectively within a moderate temperature range, typically from -40°C (-40°F) to 100°C (212°F). In colder environments, NBR maintains its flexibility better than some other rubber materials, preventing brittleness and cracking that could compromise the seal and protection of the clamped parts. In moderately high - temperature conditions, such as those in engine compartments, NBR resists softening and losing its mechanical properties, continuing to provide reliable protection and sealing. However, it's important to note that extreme temperatures beyond its rated range may reduce its performance and lifespan.

Can I install the rubber sleeve on the automotive clamp myself?

Yes, Clean the surface of the clamp thoroughly to remove any dirt, grease, or rust. This helps to ensure a better fit and adhesion if the sleeve has an adhesive lining.

Item | Rubber Sleeve for Automotive Clamps | |

Size | Customize | |

Material | NBR | |

Hardness | 70 Shore A or customize | |

Color | Black or customize any color | |

Density | 1.3g/cm³ | |

Temperature resistant | -40°C—120°C | |

Tensile strength | 5~12Mpa | |

Elongation at break | 200~900% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |