High - Temperature Resistant Leak - Proof TPV Gaskets for Industrial Machinery Sealing

- Model

- NO.L20240507006

Item specifics

- Color (General)

- Custom

- Material

- TPV

- Length

- Custom

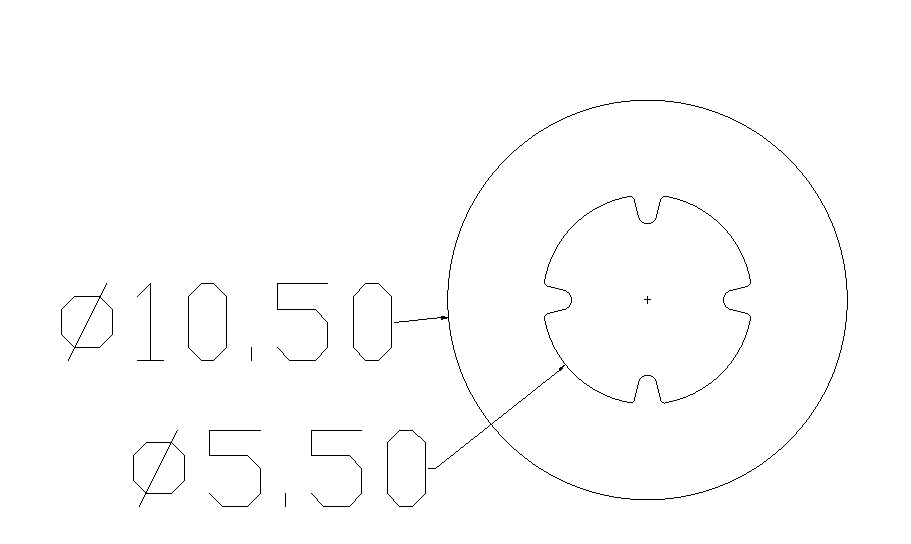

- Dimension

- Custom

- Temperature Range

- -40°C—100°C

- Shore Hardness

- 75 Shore A or customize

- Tensile strength

- 5~12Mpa

- Elongation at break

- 400%

Review

Description

TPV Gasket Introduction

Sealing Function

The primary role of a TPV gasket is to provide a leak - proof seal between two or more components. Whether used in pipes, valves, pumps, or machinery, it fills the gaps and irregularities between surfaces, preventing the escape or ingress of fluids (liquids or gases) and protecting the system from contamination, pressure loss, or environmental intrusion. Its elastic memory enables it to recover its original shape after compression, ensuring a long - lasting seal even under varying mechanical stress, vibrations, or thermal cycling.

Applications

TPV gaskets are widely used in multiple industries. In the automotive sector, they seal engine components, fuel systems, and transmission parts, withstanding the harsh conditions of high temperatures, oil exposure, and mechanical vibrations. In industrial machinery, they ensure the integrity of fluid - handling systems, protecting against leaks of chemicals, lubricants, and coolants. They are also utilized in plumbing, HVAC systems, and electrical enclosures, where their ability to resist different environmental factors and maintain a secure seal is crucial for system performance and reliability.

Cost - effectiveness

TPV gaskets offer a cost - effective sealing solution. Their long service life, combined with low installation and maintenance costs, reduces the overall cost of ownership. By minimizing the frequency of replacements and preventing costly leaks and system failures, they provide significant value to industries, making them a popular choice for applications where both performance and economy are essential.

TPV Gasket Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available Logo | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Construction & Renovation |

Material Properties

TPV exhibits excellent elasticity, similar to traditional rubber, allowing it to conform closely to mating surfaces and create a tight, reliable seal. It maintains this flexibility over a broad temperature range, from extremely cold conditions where it resists brittleness to high - heat environments without softening or losing its shape, ensuring consistent sealing performance in diverse operating conditions. TPV also boasts remarkable chemical resistance, withstanding exposure to common industrial chemicals, oils, solvents, and environmental factors such as UV radiation and ozone. This resistance helps prevent degradation, swelling, or cracking, extending the lifespan of the gasket.

1. Why is TPV a good choice for gaskets?

TPV is an excellent choice for gaskets as it combines the elasticity of rubber and the processability of thermoplastics. It offers outstanding temperature resistance, remaining flexible from extremely cold to high - heat conditions, which ensures consistent sealing performance.

2. How well do TPV gaskets perform under extreme temperatures?

TPV gaskets perform exceptionally well under extreme temperatures. In cold conditions, often down to -40°C (-40°F), TPV retains its flexibility and doesn't become brittle, ensuring a tight seal that prevents cold - related leaks. In high - temperature environments, up to around 130°C (266°F), it resists softening and maintains its shape and mechanical properties, continuing to provide a secure seal. This wide temperature tolerance allows TPV gaskets to be used in various applications, from automotive engines that generate high heat to outdoor equipment exposed to freezing winters, without compromising on sealing effectiveness.

3. How long do TPV gaskets typically last?

TPV gaskets typically have a long lifespan due to the material's robust properties. With its resistance to abrasion, chemical attack, and environmental factors like UV and ozone, TPV can endure years of exposure to harsh operating conditions. Under normal circumstances and with proper installation, TPV gaskets can last 5 - 10 years or even longer. Their ability to recover from compression and maintain elasticity over multiple usage cycles further contributes to their durability, reducing the frequency of replacements and providing a cost - effective sealing solution for various industries.

Item | TPV Gasket | |

Size | Customize | |

Material | TPV | |

Hardness | 75 Shore A or customize | |

Color | White or customize any color | |

Density | 0.9-1.0g/cm³ | |

Temperature resistant | -40°C—100°C | |

Tensile strength | 5~12Mpa | |

Elongation at break | 200~900% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |