High-Voltage Resistant PVC Sleeve for Cabinet Durable and Insulated for Electrical Safety and Protection

- Model

- NO.G2023112910

Item specifics

- Color (General)

- Custom

- Material

- PVC

- Length

- Custom

- Dimension

- Custom

- Temperature Range

- -20℃~60℃

- Shore Hardness

- 60Shore A or customize

- Tensile strength

- ≥10Mpa

- Elongation at break

- ≥150%

- Tear strength

- ≥25KN/M

Review

Description

PVC Sleeve for High Voltage Cabinet Introduction

Function and Applications

The primary function of the PVC sleeve is to protect high - voltage cables, busbars, and other electrical conductors within the cabinet. By covering these components, it provides an extra layer of insulation, reducing the risk of electrical arcing and flashovers. This is particularly important in high - voltage cabinets where the consequences of electrical failures can be severe. PVC sleeves are also used to organize and identify different electrical circuits, improving the overall manageability and maintainability of the high - voltage system.

Installation and Maintenance

Installing PVC sleeves in high - voltage cabinets is a relatively straightforward process. They can be easily slipped over the electrical conductors or components and secured in place using specialized clips, ties, or adhesive tapes. The flexibility of PVC allows for easy manipulation during installation, ensuring a snug fit without causing damage to the underlying electrical parts.

Cost - effectiveness

PVC sleeves offer a cost - effective solution for high - voltage cabinet protection. Compared to some high - end insulation materials, PVC is more affordable while still delivering reliable performance. Its long service life, combined with low installation and maintenance costs, makes it an attractive choice for power distribution companies, industrial facilities, and other organizations that rely on high - voltage electrical systems.

PvC Sleeve for High Voltage Cabinet Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Machinery & Automation Equipment |

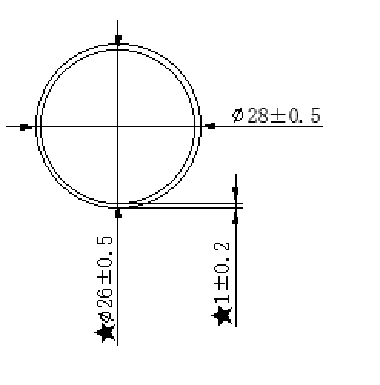

Technical Specification

EPDM rubber (ethylene propylene diene monomer rubber) is a type of synthetic rubber that is used in many applications, with outstanding resistance to oxygen, ozone, and sunlight. Additionally, it also has low temperature flexibility, excellent heat, water and steam resistance. Useful working temperature range is -60°C up to +150°C.

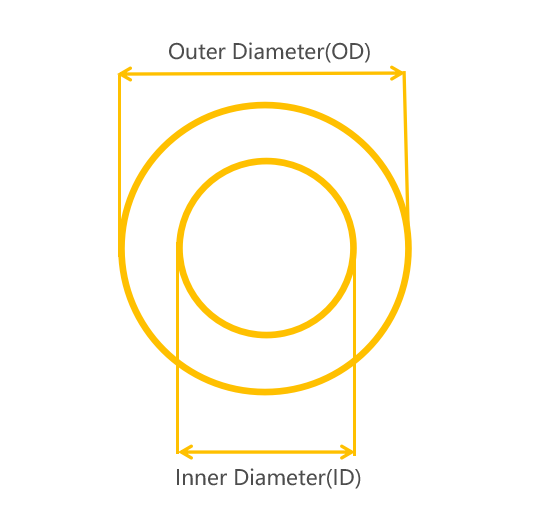

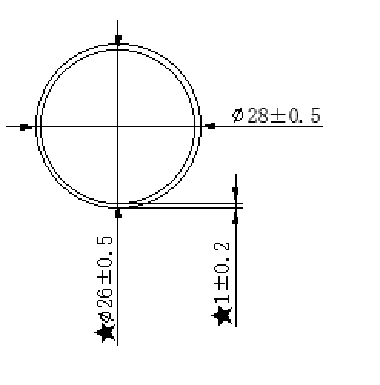

Notes on measuring pipe sizes:

Outer Diameter (OD): The measurement of the tubing's external surface and is typically the larger value.

Inner Diameter (ID): The internal measurement inside the tubing, critical for ensuring proper flow rates.

The most important thing to consider in tubing size is the combination of ID and OD. Selecting the correct measurement unit and ensuring precise compatibility are key to achieving an efficient and leak-proof liquid cooling system. These values also determine the wall thickness of your tubing, which in turn determines its flexibility and resistance to kinking.

1. Why is PVC suitable for high voltage cabinet sleeves?

PVC is suitable for high voltage cabinet sleeves because it possesses excellent electrical insulation properties that effectively prevent electrical leakage and short circuits, ensuring the safety of both equipment and personnel working around high voltage systems. Its good mechanical strength allows it to endure mechanical stress, vibrations, and impacts during cabinet operation without getting damaged easily.

2. How do PVC sleeves enhance the safety of high voltage cabinets?

PVC sleeves enhance the safety of high voltage cabinets by adding an extra layer of insulation to high voltage cables and busbars. This additional insulation significantly reduces the risk of electrical arcing and flashovers, which can lead to dangerous electrical malfunctions. By covering exposed conductors, the sleeves prevent accidental contact with live parts, protecting maintenance personnel from electric shock. Moreover, they help in organizing and clearly identifying different electrical circuits within the cabinet, reducing the chances of misconnections and improving overall operational safety.

3. How durable are PVC sleeves in high voltage cabinet applications?

PVC sleeves are quite durable in high voltage cabinet applications. Thanks to their resistance to environmental factors such as moisture, chemicals, and UV radiation, they don't degrade quickly even when exposed to the challenging conditions often found in industrial settings. The material's ability to withstand mechanical stress from the normal operation of high voltage cabinets, including vibrations and occasional impacts, ensures that the sleeves maintain their shape and protective function over an extended period.

Item | PVC Sleeve for High Voltage Cabinet | |

Size | Customize | |

Material | PVC | |

Hardness | 60 Shore A or customize | |

Color | Black or customize any color | |

Density | ≤1.30g/cm³ | |

Temperature resistant | -20℃~60℃ | |

Tensile strength | ≥10Mpa | |

Elongation at break | ≥150% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |