Durable Anti-Dust Silicone Seal for Secure Electrical Cabinet Enclosures

- Model

- NO.G20240313004

Item specifics

- Color (General)

- Custom

- Material

- Silicone

- Length

- Custom

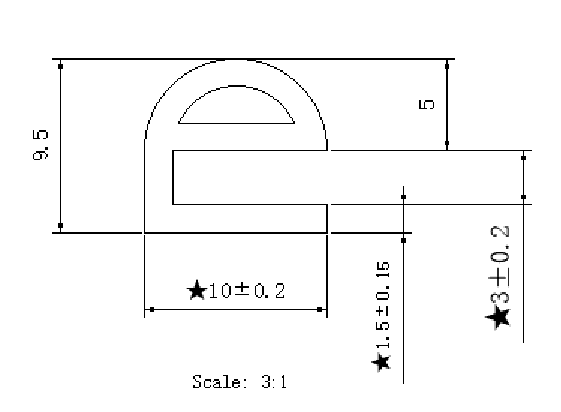

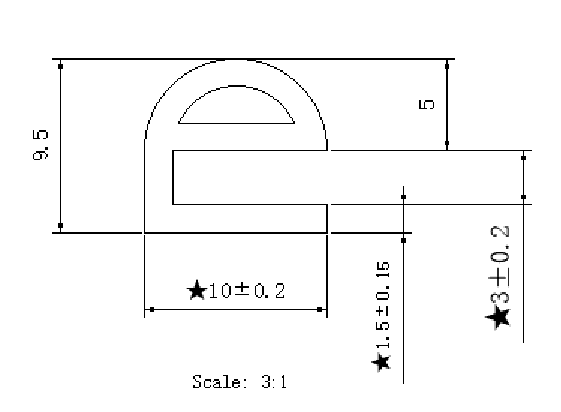

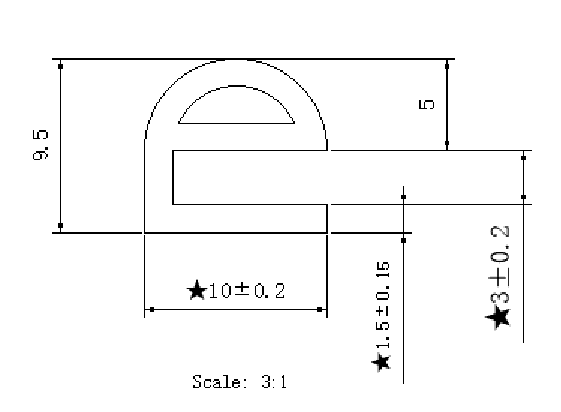

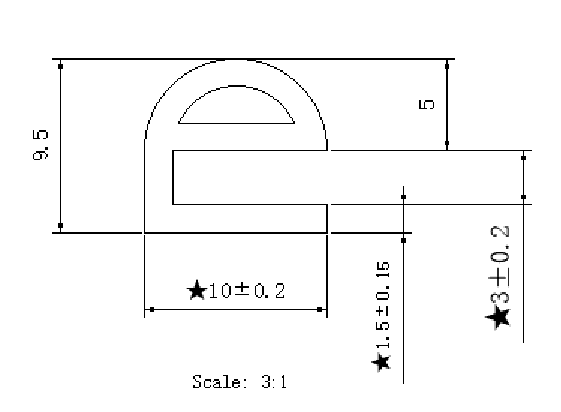

- Dimension

- Custom

- Temperature Range

- -20℃~100℃

- Shore Hardness

- 50 Shore A or customize

- Tensile strength

- ≥5Mpa

- Elongation at break

- ≥350%

- Tensile strength

- ≥12KN

Review

Description

Rubber Seal for Medical Cabin Door Introduction

Sealing Function

The primary role of the silicone rubber seal is to create an airtight and watertight barrier for medical cabin doors. In medical applications, maintaining a controlled internal environment is of utmost importance. The seal prevents the ingress and egress of air, ensuring that the cabin’s air quality, pressure, and temperature remain stable. This is vital for procedures such as isolation of infectious patients, maintaining sterile conditions for surgeries or medical treatments, and protecting sensitive medical equipment from contamination.

Applications

This silicone rubber seal is suitable for a variety of medical cabins, including isolation units, operating rooms, mobile medical units, and pharmaceutical storage cabins. In isolation units, it helps prevent the spread of infectious agents by containing contaminated air within the cabin. In operating rooms, it contributes to maintaining a sterile atmosphere, reducing the risk of surgical site infections.

Quality and Reliability

Silicone rubber seals for medical cabin doors are manufactured to high - quality standards to ensure reliability and performance. Their ability to withstand the rigors of medical environments, including frequent sterilization and exposure to various chemicals, makes them a trusted component in medical facilities. By providing a secure and consistent seal, they contribute to the overall functionality, safety, and efficiency of medical cabins, playing an essential role in modern healthcare settings.

Silicone Seal for Electrical Cabinet Door Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Electrical Equipment & Cables |

Material Properties

Silicone stands out for its exceptional biocompatibility, making it non - toxic and safe for use in medical settings where contact with patients, medical staff, and sensitive medical equipment is frequent. It does not release harmful substances or cause allergic reactions, ensuring the well - being of those within the medical cabin. This material also exhibits outstanding resistance to a wide range of disinfectants, sterilization processes, and common medical chemicals.

1. Why is silicone a suitable material for electrical cabinet door seals?

Silicone is an ideal material for electrical cabinet door seals because of its excellent electrical insulation properties, which prevent electrical leakage and ensure the safety of the equipment and personnel. It also offers remarkable resistance to a wide range of environmental factors, including moisture, dust, and various chemicals commonly found in industrial settings. Silicone maintains its flexibility across a broad temperature spectrum, from extremely cold conditions that could make other materials brittle to high - heat environments near electrical components, ensuring a consistent and reliable seal.

2. How effectively does a silicone seal for electrical cabinet doors prevent dust and moisture ingress?

A silicone seal for electrical cabinet doors prevents dust and moisture ingress very effectively. Its elastic nature allows it to conform tightly to the surfaces of the door and the cabinet frame, filling any gaps or irregularities. The dense structure of silicone acts as a barrier, blocking even the smallest dust particles from entering the cabinet, which can otherwise cause electrical malfunctions by accumulating on components or interfering with connections.

3. Are silicone seals for electrical cabinet doors easy to install?

Yes, silicone seals for electrical cabinet doors are generally easy to install. Many silicone seals come with adhesive backing, enabling users to simply peel off the protective layer and firmly press the seal onto a clean, dry surface of the cabinet door frame.

Item | Silicone Seal for Electrical Cabinet Door | |

Size | Customize | |

Material | Silicone | |

Hardness | 50Shore A or customize | |

Color | White or customize any color | |

Density | ≤1.16g/cm³ | |

Temperature resistant | -20℃~100℃ | |

Tensile strength | ≥5Mpa | |

Elongation at break | ≥350% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |