Easy-to-Clean Hygienic Rubber Seal for Secure Medical Cabin Door Sealing Solutions

- Model

- NO.F20240110

Item specifics

- Color (General)

- Custom

- Material

- EPDM

- Length

- Custom

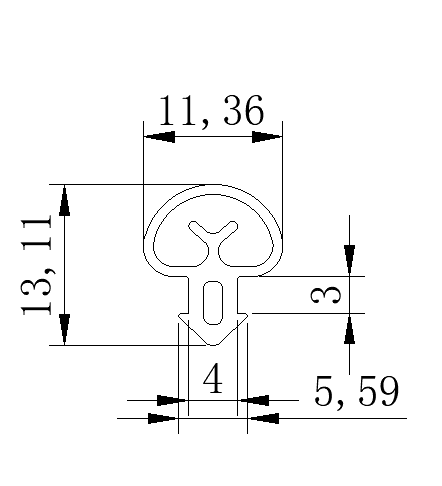

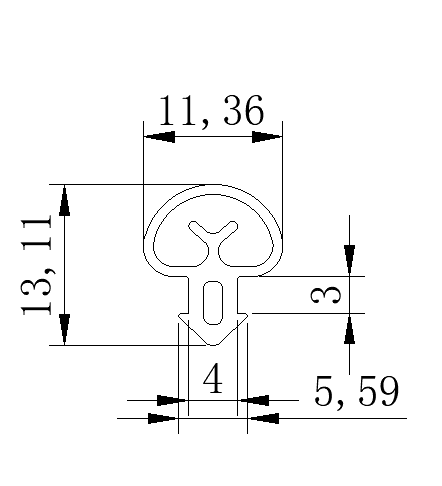

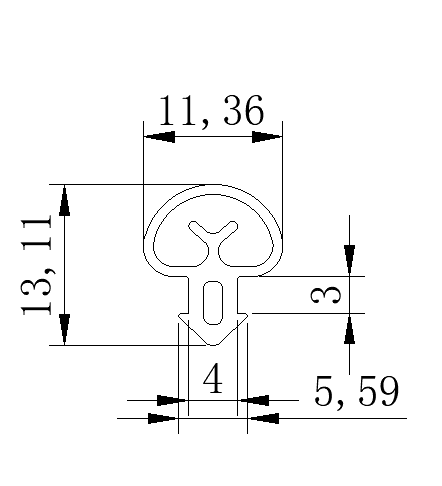

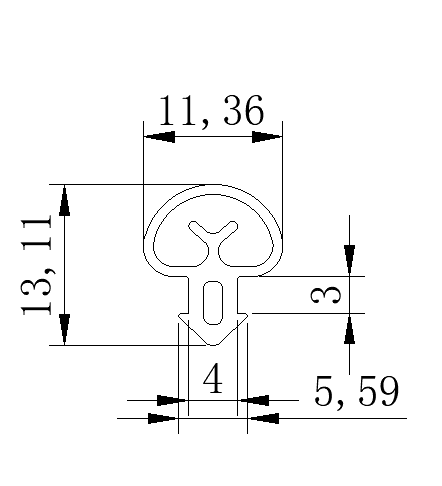

- Dimension

- Custom

- Temperature Range

- -45°C—125°C

- Shore Hardness

- 50-95 Shore A or customize

- Tensile strength

- 5~12Mpa

- Elongation at break

- 400%

Review

Description

Rubber Seal for Medical Cabin Door Introduction

Function and Applications

The primary function of the EPDM rubber seal for medical cabin doors is to create a secure and airtight barrier. By sealing the gap between the door and the cabin frame, it prevents the ingress of dust, bacteria, viruses, and other contaminants, helping to maintain a sterile environment inside the medical cabin. This is essential for procedures that require strict aseptic conditions, such as surgeries, patient isolations, and the storage of sensitive medical equipment and supplies.

Installation and Maintenance

Installing the EPDM rubber seal on a medical cabin door is typically a straightforward process. Its flexibility allows it to be easily shaped and positioned to fit the contours of the door and frame. Many EPDM seals come with adhesive backing or pre - designed grooves and clips for easy attachment, ensuring a secure and tight fit. The installation can be carried out by trained technicians or maintenance staff with minimal tools and effort.

Cost - effectiveness

The EPDM Rubber Seal for Medical Cabin Door offers a cost - effective solution for maintaining the integrity and functionality of medical cabins. Its long lifespan, thanks to its durable material properties, reduces the frequency of replacements, saving on both parts and labor costs over time.

Rubber Seal for Medical Cabin Door Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Machinery & Automation Equipment |

Technical Specification

EPDM rubber (ethylene propylene diene monomer rubber) is a type of synthetic rubber that is used in many applications, with outstanding resistance to oxygen, ozone, and sunlight. Additionally, it also has low temperature flexibility, excellent heat, water and steam resistance. Useful working temperature range is -45°C up to +125°C.

What are the functions of a rubber seal for a medical cabin door?

It mainly provides a tight seal to prevent air leakage, which is crucial for maintaining a sterile environment in the medical cabin. It also helps in sound insulation, reducing noise interference during medical procedures. Additionally, it stops dust and small particles from entering, safeguarding the cleanliness of the cabin.

How to clean and maintain the seal?

Regularly clean it with medical - approved cleaning agents and a soft cloth. Check for signs of wear, such as cracks or loss of elasticity. Replace the seal if it shows significant damage to maintain the cabin's proper sealing.

What affects the seal's performance over time?

Exposure to strong disinfectants, frequent door opening and closing, and high - humidity conditions in the medical cabin can cause the rubber to degrade.

Item | Rubber Seal for Medical Cabin Door | |

Size | Customize | |

Material | EPDM | |

Hardness | 50-95 Shore A or customize | |

Color | Customize any color | |

Density | 0.6-1.45g/cm³ | |

Temperature resistant | -45°C—125°C | |

Tensile strength | 5~12Mpa | |

Elongation at break | 200~900% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |