Durable UV-Resistant Solar Mounting Rubber Bracket Pad for Long-Lasting Solar System Protection

- Model

- NO.F20240604

Item specifics

- Color (General)

- Custom

- Material

- PVC

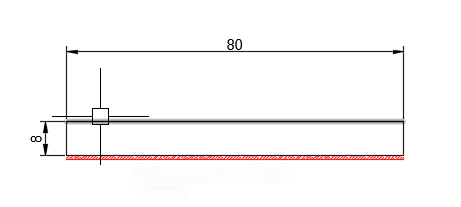

- Length

- Custom

- Dimension

- Custom

- Temperature Range

- -20°C—80°C

- Shore Hardness

- 75 Shore A or customize

- Tensile strength

- 5Mpa

- Elongation at break

- 200%

Review

Description

Solar Mounting Rubber Bracket Pad Introduction

The Solar Mounting Rubber Bracket Pad crafted from PVC (Polyvinyl Chloride), is a crucial component in solar panel installation systems.

Compared with EPDM Rubber

While EPDM rubber also offers good weather and chemical resistance, PVC pads have a lower cost. EPDM rubber manufacturing processes can be more complex and expensive, resulting in higher - priced products. PVC pads, on the other hand, provide similar performance in many aspects at a more affordable price point. However, EPDM rubber may have better flexibility at extremely low temperatures compared to PVC, which can become slightly stiffer in very cold conditions.

Material Advantages

PVC is a widely used thermoplastic polymer known for its versatility, durability, and cost - effectiveness. Composed of vinyl chloride monomers linked through polymerization, PVC can be formulated into various types, including rigid and flexible forms, by adjusting the addition of plasticizers and other additives. For solar mounting rubber pads, flexible PVC is typically employed, offering a blend of rubber - like properties and plastic - based resilience.

Solar Mounting Rubber Pad Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | New Energy |

Technical Specification

In extrusion, the heated PVC compound is forced through a die to create a continuous shape, which can then be cut into individual pads. Injection molding is used for more complex shapes, where the compound is injected into a mold cavity under high pressure. Calendaring involves passing the compound between heated rollers to form flat sheets, which are later cut into pads. Quality control measures are implemented throughout the process to ensure consistent thickness, shape, and performance.

1. What are the main benefits of using PVC for solar mounting rubber pads?

PVC offers several key advantages. It provides excellent weather resistance, protecting the pads from UV rays, rain, and extreme temperatures ranging from -20°C to 70°C. It also has good chemical resistance against common outdoor substances, is electrically insulating for safety, cost-effective due to its affordable raw materials and efficient manufacturing, and is easy to install thanks to its lightweight and flexible nature.

2. Can PVC solar mounting rubber pads withstand long - term sunlight exposure?

Yes, PVC pads have inherent resistance to UV radiation. They are designed to endure long - term sunlight exposure without significant degradation, discoloration, or cracking, ensuring their functionality and integrity remain intact over time in outdoor solar panel installations.

3. How does the temperature affect the performance of PVC rubber pads?

PVC pads perform well within the temperature range of -20°C to 70°C. In cold temperatures close to -20°C, they may become slightly stiffer but still maintain sufficient flexibility for cushioning and insulation. At the higher end near 70°C, the material retains its shape and properties. However, temperatures outside this range can cause the pads to become brittle or soften, potentially reducing their effectiveness.

Item | Solar Mounting Rubber Pad | |

Size | Customize | |

Material | PVC | |

Hardness | 75 Shore A or customize | |

Color | Black or customize any color | |

Density | 1.3g/cm³ | |

Temperature resistant | -20°C—80°C | |

Tensile strength | 5Mpa | |

Elongation at break | 200% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |