Easy-to-Install Multi-Purpose Decorative Tube for Creative Backpack Personalization

- Model

- NO.G20231117006

Item specifics

- Color (General)

- Custom

- Material

- TPV6375N

- Length

- Custom

- Dimension

- Custom

- Temperature Range

- -20℃~60℃

- Shore Hardness

- 80Shore A or customize

- Tensile strength

- ≥5.8Mpa

- Elongation at break

- 400%

- Tear strength

- ≥26KN

- Density

- ≤0.98cm³

Review

Description

Rubber Polished Tube for Paper Rolls Introduction

Thermal Stability

TPV exhibits good thermal stability, which is essential in paper manufacturing facilities where temperature variations can occur. The tubes can withstand both moderately high and low temperatures without losing their mechanical properties. Whether in hot drying processes or cooler storage areas, TPV rubber polished tubes maintain their strength, elasticity, and smooth surface finish, ensuring consistent performance in different environmental conditions.

Cost - effectiveness and Longevity

Due to TPV's durability, resistance to wear and tear, and chemical stability, rubber polished tubes made from this material offer a cost - effective solution for paper roll handling. Their long service life reduces the frequency of tube replacements, minimizing maintenance costs and downtime in paper production lines. The combination of high performance and economic efficiency makes TPV rubber polished tubes a preferred choice for the paper industry.

Chemical Resistance

In the paper processing environment, TPV rubber polished tubes may come into contact with various chemicals, such as inks, solvents, and cleaning agents. TPV's inherent chemical resistance protects the tube from degradation, swelling, or discoloration caused by these substances. This resistance not only extends the service life of the tube but also prevents any potential contamination of the paper rolls from the tube material itself.

Rubber Polished Tube for Paper Rolls Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Office & School Supplies |

Material - TPV Advantages

TPV is a unique blend of thermoplastics and fully vulcanized rubber, offering a remarkable combination of properties. It inherits the processability of thermoplastics, allowing for precise manufacturing of polished tubes with consistent dimensions and smooth surfaces. At the same time, it retains the excellent elasticity, durability, and chemical resistance of rubber. This makes TPV an ideal material choice for applications where high - performance and long - term reliability are required.

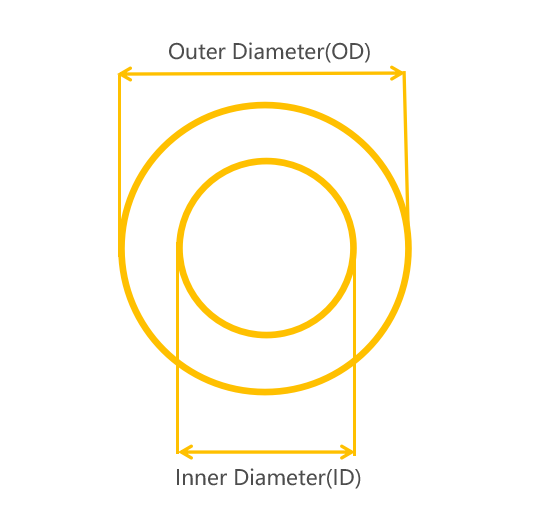

Notes on measuring pipe sizes:

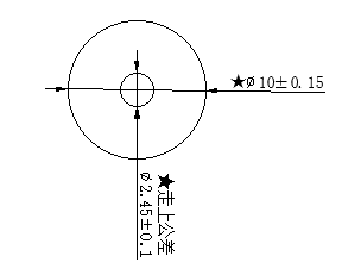

Outer Diameter (OD): The measurement of the tubing's external surface and is typically the larger value.

Inner Diameter (ID): The internal measurement inside the tubing, critical for ensuring proper flow rates.

The most important thing to consider in tubing size is the combination of ID and OD. Selecting the correct measurement unit and ensuring precise compatibility are key to achieving an efficient and leak-proof liquid cooling system. These values also determine the wall thickness of your tubing, which in turn determines its flexibility and resistance to kinking.

1. Why are TPV rubber polished tubes suitable for paper roll applications?

TPV rubber polished tubes are well - suited for paper roll applications because of the material's unique properties. TPV combines the processability of thermoplastics with the durability and elasticity of rubber, allowing for the production of tubes with a precisely polished surface that minimizes friction against paper.

2. Can TPV rubber polished tubes withstand different chemicals used in paper production?

Yes, TPV rubber polished tubes can withstand various chemicals used in paper production. TPV has inherent chemical resistance properties that enable it to resist degradation, swelling, or discoloration when exposed to common substances like inks, dyes, solvents, and cleaning agents in the paper manufacturing process.

3. How does the thermal stability of TPV benefit paper roll handling?

The thermal stability of TPV benefits paper roll handling by allowing the rubber polished tubes to maintain their performance across different temperature conditions in paper manufacturing and storage facilities. In processes involving heat, such as drying or curing stages, TPV tubes won't soften, deform, or lose their elasticity, ensuring they can continue to support and protect paper rolls effectively.

Item | Rubber Sponge | |

Size | Customize | |

Material | TPV6375N | |

Hardness | 80Shore A or customize | |

Color | Black or customize any color | |

Density | ≤0.98cm³ | |

Temperature resistant | 40±2°C | |

Tensile strength | ≥5.8Mpa | |

Elongation at break | >400% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |