High-Performance Rubber Foam Tube for Printer Noise Reduction and Vibration Dampening

- Model

- NO.G20231127011

Item specifics

- Color (General)

- Custom

- Material

- TPV6375N

- Length

- Custom

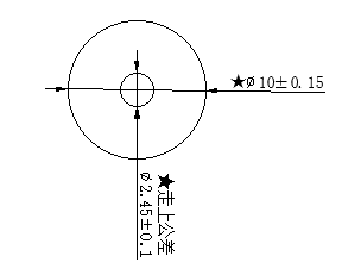

- Dimension

- Custom

- Temperature Range

- -20℃~60℃

- Shore Hardness

- 80Shore A or customize

- Tensile strength

- ≥5.8Mpa

- Elongation at break

- ≥400%

- Tear strength

- ≥26KN

Review

Description

Rubber Foam Tube for Printer Introduction

Shock Absorption and Vibration Damping

In printers, mechanical vibrations can affect print quality and cause wear on internal components. The foam structure of TPV tubes provides excellent shock absorption, reducing the impact of vibrations generated during the printer's operation. This helps to maintain stable print head movement, ensuring sharp and accurate prints while also extending the lifespan of printer parts.

Noise Reduction

The elastic and porous nature of TPV rubber foam effectively muffles the sounds produced by the printer's moving parts. By minimizing noise, it creates a more pleasant working environment, especially in office settings where multiple printers may be in operation simultaneously.

Chemical Resistance:

Printers often come into contact with various substances, including inks, cleaning agents, and solvents. TPV exhibits good resistance to a wide range of these chemicals, preventing degradation or swelling of the foam tube. This ensures that the tube remains functional over time and does not contaminate the printer or affect the integrity of the printing process.

Rubber Foam Tube for Printer Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Office & School Supplies |

Material Properties

TPV is a dynamically vulcanized blend of thermoplastics and elastomers, which endows it with the best of both worlds. It has the processability of thermoplastics, allowing for easy extrusion and molding into foam tubes, while retaining the elasticity and resilience typical of rubber. This unique combination makes TPV an ideal material for printer applications where precision manufacturing and consistent quality are crucial.

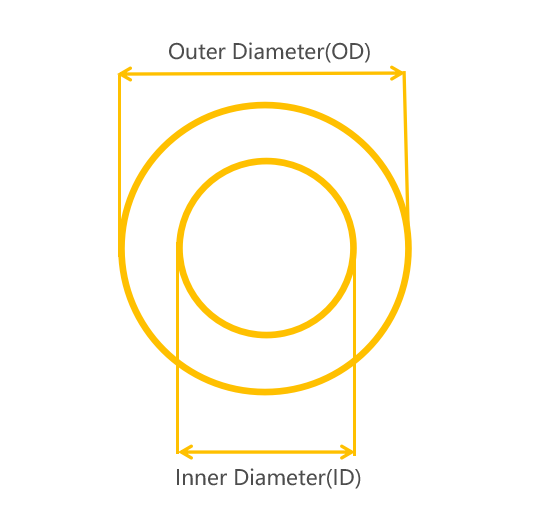

Notes on measuring pipe sizes:

Outer Diameter (OD): The measurement of the tubing's external surface and is typically the larger value.

Inner Diameter (ID): The internal measurement inside the tubing, critical for ensuring proper flow rates.

The most important thing to consider in tubing size is the combination of ID and OD. Selecting the correct measurement unit and ensuring precise compatibility are key to achieving an efficient and leak-proof liquid cooling system. These values also determine the wall thickness of your tubing, which in turn determines its flexibility and resistance to kinking.

1. Why is TPV a good choice for rubber foam tubes in printers?

TPV is an excellent choice for printer rubber foam tubes because it combines the benefits of thermoplastics and elastomers. Its processability allows for precise manufacturing to fit the specific requirements of printers. The elastic nature of TPV provides outstanding shock absorption and vibration damping, which is crucial for maintaining the stability of print heads and ensuring high - quality prints. Additionally, TPV has good chemical resistance against common printer substances like inks and cleaning agents, preventing degradation and contamination. Its thermal stability enables it to withstand the heat generated during printer operation without deforming, while its lightweight and flexible properties make it easy to install and route within the printer's confined spaces.

2. How do TPV rubber foam tubes reduce noise in printers?

TPV rubber foam tubes reduce noise in printers through their unique structure and material properties. The porous foam structure of TPV acts as a sound absorber, capturing and dissipating the sound waves produced by the printer's moving parts. As mechanical components such as motors and gears operate, they generate vibrations that create noise. The elastic nature of TPV helps to dampen these vibrations, reducing the amplitude and the resulting noise. By minimizing both the vibration - induced noise and the direct sound transmission, TPV rubber foam tubes contribute to a quieter printer operation, improving the working environment, especially in office settings where multiple printers are used.

3. How does the thermal stability of TPV benefit printer operations?

The thermal stability of TPV benefits printer operations in several ways. Printers generate heat during operation due to the continuous movement of components and the electrical processes involved. TPV's ability to withstand a moderate temperature range ensures that the rubber foam tube does not deform, shrink, or lose its elastic properties under these operating temperatures.

Item | Rubber Foam Tube for Printer | |

Size | Customize | |

Material | TPV6375N | |

Hardness | 80Shore A or customize | |

Color | Black or customize any color | |

Density | ≤0.98g/cm³ | |

Temperature resistant | -20℃~60℃ | |

Tensile strength | ≥5.8Mpa | |

Elongation at break | >400% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |