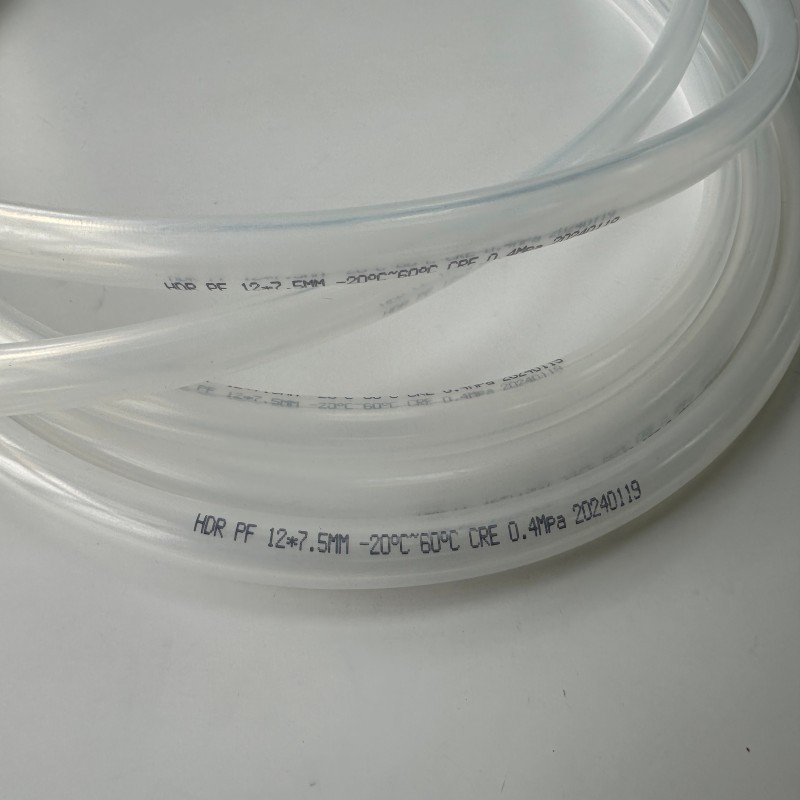

Flexible Temperature-Resistant Hose for Efficient Electrolyte Handling in Harsh Conditions

- Model

- NO.F20240105

Item specifics

- Color (General)

- Custom

- Material

- EVA

- Length

- Custom

- Temperature Range

- -20°C—60°C

- Shore Hardness

- 90 Shore A or customize

- Tensile strength

- ≥7Mpa

- Elongation at break

- 350%

- Tear strength

- 15KN

- Size

- φ12.0*φ8.0mm or customize

Review

Description

Electrolyte Rubber Hose Introduction

Material Advantages

The Electrolyte Rubber Hose tube is crucial for battery production lines to transfer electrolytes accurately, and also plays a key role in industrial electroplating by safely delivering corrosive electrolytes.

Customization Options

EVA could produce the tubing with enough length to fully connect any size loop.

And available to custom colors, such as black, white, pink, etc.

Good Sealing Performance

EVA material has excellent sealing properties. The Electrolyte Rubber Hose can form a tight seal, preventing leakage of the transported electrolytes. This is essential for applications where fluid tightness is critical, such as in battery manufacturing processes or in chemical plants where precise control of electrolyte flow is required.

Electrolyte Rubber Hose Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | New Energy |

Technical Specification

The proportion of vinyl acetate in EVA typically ranges from 10% to 40%, and this ratio significantly impacts the material's properties, including elasticity, impact resistance, and clarity.

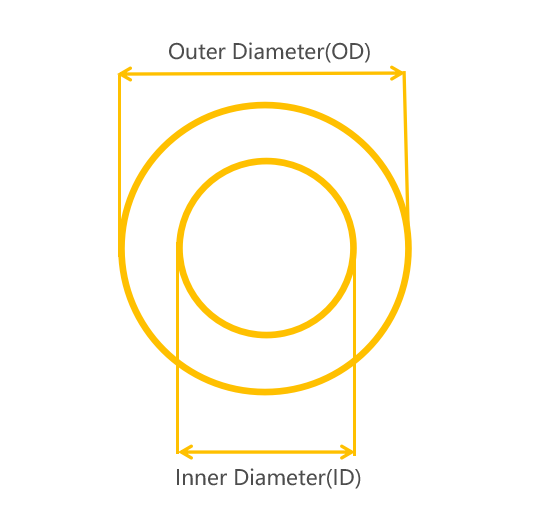

Electrolyte Rubber Hose sizes:

Outer Diameter (OD): The measurement of the tubing's external surface and is typically the larger value.

Inner Diameter (ID): The internal measurement inside the tubing, critical for ensuring proper flow rates.

The most important thing to consider in tubing size is the combination of ID and OD. Selecting the correct measurement unit and ensuring precise compatibility are key to achieving an efficient and leak-proof liquid cooling system. These values also determine the wall thickness of your tubing, which in turn determines its flexibility and resistance to kinking.

Are EVA hoses resistant to UV exposure or outdoor use?

EVA has moderate UV resistance but is not fully weatherproof for prolonged outdoor use. For outdoor applications, consider UV-stabilized EVA variants or protective coatings to prevent surface degradation (e.g., discoloration or brittleness).

Can EVA hoses handle high-pressure electrolyte systems?

Standard EVA hoses are designed for low to medium pressure (typically ≤10 bar / 145 psi). For high-pressure applications (e.g., industrial pumps), consult the manufacturer for reinforced variants (e.g., fabric or wire braiding) to enhance pressure tolerance.

How long is the typical lifespan of an EVA hose?

With proper use and maintenance, EVA hoses can last 3–5 years in standard industrial environments. Lifespan may vary based on factors like temperature, chemical exposure, and mechanical stress (e.g., bending or pressure).

Item | Electrolyte Rubber Hose | |

Size | Customize | |

Tear strength | 15KN | |

Hardness | 90 Shore A or customize | |

Color | White or customize any color | |

Density | 0.95g/cm³ | |

Temperature resistant | -20°C—60°C | |

Tensile strength | ≥7Mpa | |

Elongation at break | >500% | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |