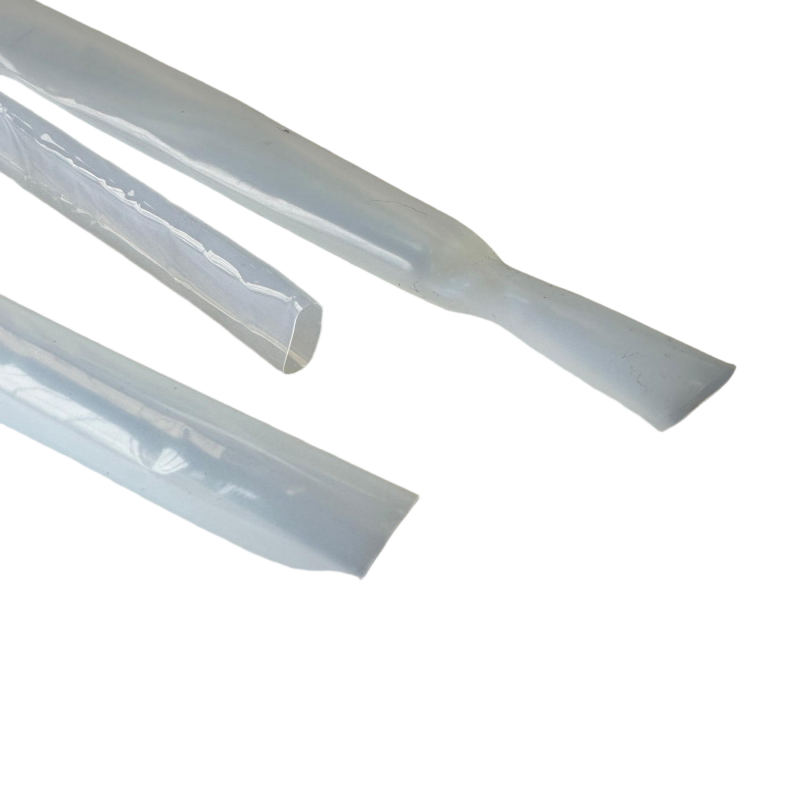

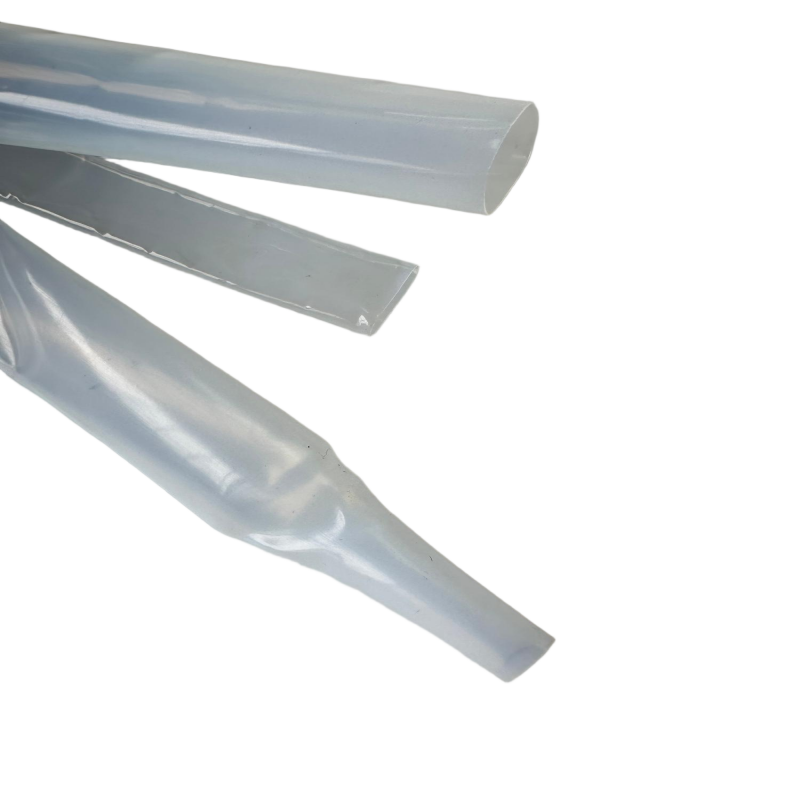

Flexible Electrical Insulation Heat Shrink Tubing Silicone Rubber Tube Black Gray Red Shrinkage Sleeve

Item specifics

- Color (General)

- Customized according to customers

- Material

- Silicone(Polysiloxane)

- Length

- Custom

- Dimension

- Customized according to customers

- Tensile Strengtn after aging (MPa)

- UL224 158°CX168hr

- Processing Service

- Moulding, Cutting

- Size

- ID 1mm-70mm

- Application

- Microwave Waveguide;Metal boxes;Automotive;Medical

- Rated Voltage

- 220 V

- Style

- Conductive powder filled silicone/fluorosilicone

Review

Description

Bus Windshield Washer Silicone Tube Introduction

Silicone rubber insulating sleeves are high-performance protective components designed to provide reliable electrical insulation, thermal resistance, and mechanical protection for wires, cables, hoses, and other industrial components. Made from high-quality silicone rubber materials, these sleeves stand out for their excellent flexibility, weather resistance, and stability across a wide temperature range (typically -60°C to 200°C, with specialized grades capable of withstanding higher temperatures up to 260°C).

Customization Options

SILICONEcould produce the tubing with enough length to fully connect any size loop.

And available to custom colors, such as black, white, pink, etc.

Common applications span multiple industries: electronics (insulating wires in smartphones, laptops, and circuit boards), automotive (protecting engine hoses and wiring from high heat), aerospace (withstanding extreme temperature fluctuations), home appliances (insulating heating elements in ovens or water heaters), and industrial machinery (shielding cables from mechanical wear and chemical exposure).

Insulating Sleeve Silicone Rubber Properties:

| Length | Customizable | OEM/ODM | Available |

| Logo | Customer Logo Available | Lead Time | 10 Days |

| MOQ | 100 Meters | Application | Other |

Technical Specification

Key features include strong electrical insulation (high dielectric strength to prevent current leakage), resistance to aging, ozone, UV rays, and most chemicals (such as oils, acids, and alkalis), as well as good flame retardancy (meeting international safety standards like UL94 V-0). Their soft, elastic texture allows for easy installation—even on irregularly shaped components—while maintaining a tight fit to avoid slipping.

1. What temperature range can silicone rubber insulating sleeves tolerate?

Most standard silicone rubber insulating sleeves work reliably between -60°C (-76°F) and 200°C (392°F). For high-temperature applications (e.g., near industrial furnaces or aerospace components), specialized high-grade sleeves are available, with some models enduring up to 260°C (500°F) for short periods. Avoid exposing sleeves to temperatures beyond their rated range, as this may degrade insulation performance.

2. Are these sleeves waterproof?

Yes, silicone rubber naturally has water-resistant properties, making the sleeves effective at preventing moisture intrusion. However, "waterproof" does not mean fully submersible for long periods (unless specified as "submersible-grade" by the manufacturer). For outdoor or damp environments, confirm the sleeve’s IP rating (e.g., IP67 for dust and water resistance) before use.

3. How do I choose the right size of insulating sleeve?

Select a sleeve with an inner diameter (ID) slightly smaller than the outer diameter (OD) of the component you’re covering (e.g., a wire with a 5mm OD works best with a sleeve with a 4-4.5mm ID). This ensures a snug fit, as silicone rubber stretches slightly during installation. Measure the component’s OD accurately—if the sleeve is too loose, it may slip; if too tight, it may tear during application.

Item | Insulating Sleeve Silicone Rubber | |

Size | Customize | |

Material | 100% Silicone Material | |

Basic | Silicone,fluorosilicone | |

Tensile Strengtn after aging (MPa) | UL224 158°CX168hr | |

Application | Microwave Waveguide;Metal boxes;Automotive;Medical device;Industrial | |

Density | ≤1.16/cm³ | |

Temperature resistant | 220 V | |

Rated Voltage | ≥7Mpa | |

Style | Insulating Sleeve Silicone Rubber | |

Lead time | 3 days for sample, 15 days for batch order | |

Packing method | Carton/ PE bag / Wooden pallet / Paper roll | |

Price tip | The price above is for your reference, final actual price depends on your design,material request, surface treatment, order quantity, package request, etc. | |